The health and environmental effects of the nuclear fuel cycle, from ore extraction to waste disposal, have been documented for over half a decade, beginning with the earliest studies of underground uranium miners in the United States. Because of the long-recognized ability of ionizing radiation to induce various types of cancer, many of the studies of health effects have focused on this disease. In addition, however, there are non-cancer effects from acute exposure, such as burns and radiation sickness, as well as potential genetic effects on offspring of workers in the industry. In the uranium mining and milling process, there are respiratory hazards from inhaling silica dust and heavy metals, such as vanadium, in the ore. In the conversion and fuel enrichment process, there are acids that may also produce adverse skin and respiratory effects. And in fuel transportation, reactor operations, and waste management, there are numerous opportunities for accidental exposures and spills that may affect workers and nearby residents. The following sections describe some of the epidemiologic studies that have documented these health effects and note some of the impacts of the uranium fuel cycle on the natural environment.

Uranium Mining

Like most mining operations, workers are exposed to physical hazards from working underground and inhaling dust. Uranium mining carries an additional risk from radon gas, which is a radioactive decay product of the ore in both underground and surface mining. Inhaled radon has been recognized to cause lung cancer for many decades and has been the subject of studies of miners in Australia, Canada, and the United States since the 1950s. The most comprehensive review of these studies to date was done by the U.S. National Academy of Sciences, and it concluded that there was a dose-dependent increase in lung cancer with increasing exposure to alpha radiation from radon inhaled by the miners (U.S. National Academy of Sciences, 1999). In fact, the largest cumulative radiation exposure in the entire nuclear fuel cycle is to miners. This exposure burden in many countries falls disproportionately on poor and indigenous peoples. Uranium mining also produces tailings, or mine waste, that can also give off radon gas and be hazardous to those people nearby. The tailings themselves constitute a radioactive waste that must be managed so as not to be transported by wind or rain into populated areas.

Uranium Milling

Like mining, milling of uranium ore entails respiratory exposures to dusts and heavy metals, as well as radioactive decay products from uranium ore. Here again, numerous studies of uranium millers have been conducted over the past several decades, and similar conclusions pertain to risks experienced by those engaged in milling the ore into fine particles for later conversion and enrichment. If an acid leach process is used, millers may also be at increased risk of reactive airways dysfunction syndrome from inhaling acid mists. One of the environmental effects created in some uranium mill towns is contaminated building materials and cement used in paving sidewalks. For example, in Monticello Utah, the uranium mill tailings were used to make mortar for constructing fireplaces in private homes, as well as cement for town sidewalks. This, in addition to dust blowing from the mill waste piles, created a serious environmental radiation hazard that had to be remediated over a period of several years in the late 1990s and the early part of this century. The existing mill waste piles were covered with topsoil and left in place, rather than create another dust and radiation hazard by transporting the waste to another secure disposal site.

Conversion And Enrichment

This process involves acidic conversion of uranium to uranium-hexafluoride, and subsequent enrichment of the uranium-235 content of the ore by a variety of methods. The acidic conversion confers risks to the workers involved, and there are radiation risks at all further stages of the work, including fabrication of the fuel pellets to be transported to nuclear power plants. Workers in the conversion and enrichment plants are monitored for radiation exposure, and applicable limits for annual external and internal doses are invoked.

Power Plant Operation

Workers in power plants are likewise monitored because of the potential for receiving radiation exposure from routine operations, spills, leaks, and unexpected incidents. Licensing and regulatory agencies, as well as the electric power utilities themselves, keep track of such monitoring and incident reports, and cumulative doses are noted for workers throughout the world. These are summarized in international reports from the United Nations Scientific Committee on the Effects of Atomic Radiation (UNSCEAR), as well as country-level agencies, and represent some of the most detailed information available on radiation exposures in a large workforce (UNSCEAR, 2005). Studies of power plant workers have been done in the UK, Canada, the United States, France, and several other countries, and are summarized in numerous reports (Cardis et al., 1995; U.S. National Academy of Sciences, 2005). The epidemiologic record shows that power plant workers have experienced increased mortality due to leukemia and other cancers.

Furthermore, residents near nuclear power plants are occasionally exposed to releases or spills of radioactive materials from malfunctioning filters or transportation accidents. There have been a few studies of communities near nuclear facilities that showed increased leukemia, especially in children and young adults (Beral et al., 1993). These results have been questioned because of a lack of individual exposure measurements, but they are certainly consistent with effects seen in power plant workers.

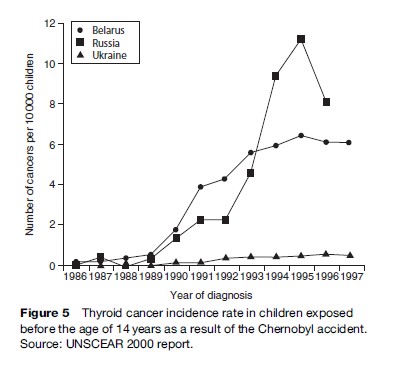

The impact of the 1986 Chernobyl nuclear plant disaster is an unprecedented example of the immediate and long-term effects of environmental radiation emissions on those who lived in Ukraine, Belarus, and surrounding areas in Central Europe. Here, the radioactive material was released in a powerful steam explosion that carried debris in the upper atmosphere for hundreds of miles, exposing children and adults to radioactive iodine and mixed fission products both directly by fallout and indirectly through the food chain. The environmental contamination continues into the present century, and some areas around the plant are still uninhabitable. The human impact included the 30 or more deaths in power plant workers immediately following the explosion, up to 900 cases of thyroid cancer, primarily in children in Ukraine and Belarus (see Figure 5), and ongoing cancer and non-cancer health effects in emergency workers (called liquidators) and other residents in affected areas. The lowest estimate of the number of deaths attributable to the power plant disaster is 4000 (IAEA, 2005), but there are credible estimates an order of magnitude larger than this (Scherback, 1996). The psychological effects, sometimes referred to as ‘pervasive fatalism,’ and effects on wildlife and forests are harder to quantify but are no doubt considerable, especially in Ukraine.

Fuel Reprocessing And High-Level Waste Disposal

Some countries have established fuel reprocessing plants to handle spent fuel from power plants and extract plutonium for weapons or breeder reactor fuel. In some instances, there is concern that these facilities may be having adverse health and environmental effects from releases of radioactive materials. For example, a large reprocessing plant in La Hague, France has been the focus of concern about leukemia rates in nearby communities. The problem of high-level waste disposal from power reactors has been handled differently in different countries. Most of the 115 power reactors in the United States, for example, still keep high-level waste in reactor pools or on-site storage buildings. At present, this waste represents a potential radiation hazard, and new storage technologies, such as stainless steel casks, are being developed. A permanent repository in Yucca Mountain, Utah, has been debated for years but is not yet approved for use. In other countries, vitrification and burial of high-level wastes is the method used, but it is not clear what the long-term effects of these methods will be.

Decommissioning And Dismantlement

All nuclear power plants eventually become too old, and the metal parts too brittle, to continue safe operation. The final stage in the life cycle of a nuclear power plant, when it is closed, dismantled, and the radioactive building materials are transported away to permanent storage, also involves radiation risks. Here again, the workers who are exposed to the radioactive parts of the building, as well as the transportation workers, will have increased health risks from their exposures. If there are accidental radioactive releases to nearby residents on the transportation routes, there may be health risks for these individuals, as well.

The Future Of Nuclear Power

Future trends of nuclear power use into the twenty-first century are uncertain. Technological improvements and design innovations have made nuclear power generation more efficient, safer, and more affordable than during its early years of existence, yet key problems such as nuclear waste disposal, public fear and resistance, high comparative costs, and the relation to global nuclear arms proliferation remain unresolved. Discussion of some of the latest research on these issues and on recent technological advances follows.

Improvement in nuclear reactor design and function is a topic currently receiving much international attention and investment by governments and corporations. There are fewer than 10 major power plant designers and vendors worldwide, with the largest being British Nuclear Fuels, the French government’s Framatome, and the General Electric. These three continue to design and market improved nuclear reactor models. Although the majority of the world’s existing power reactors – over 82% (WNA website) – are pressurized water reactors (PWRs) or boiling water reactors (BWRs), which burn enriched uranium to create electricity, two unique and potentially influential nuclear reactor models are the so-called ‘breeder’ reactor and the pebble bed reactor.

Breeder reactors, or ‘fast neutron reactors,’ currently operate in France, Japan, India, and Russia, although only one in each country, and only Russia’s is used for commercial power production (WNA website). Their defining characteristic is that they not only burn enriched uranium in the power production process, but they also burn and produce fissile plutonium, which itself can be used to produce power, though only after a specialized reprocessing step that takes place outside of the original reactor. In essence, breeder reactors produce more fuel than they use, thus requiring much less uranium input per unit of energy output. Breeder reactors are seen by some as a viable means of making nuclear power production sustainable in the future. Light water reactors (including PWRs and BWRs), which make up most operable reactors today, use only 1% of the uranium input, leaving 99% as waste (Botkin and Se´ller, 2005). Breeder reactors can extract up to 60 times as much energy from the same amount of uranium (IAEA website). The drawbacks to breeder reactors are their high cost and the fact that the surplus plutonium they produce is suitable for use in the production of nuclear weapons and thus creates added security problems.

Pebble bed reactors are a relatively new gas-cooled design that has yet to be marketed commercially. Spearheaded by the South African vendor Eskom, these reactors are often touted as the next evolution of nuclear power technology. Instead of using the rod-containing fuel assemblies popular in the water-cooled reactors, this design uses spherical fuel elements, or ‘pebbles.’ Each pebble contains several thousand uranium fuel kernels, which are molded into a graphite and ceramic sphere about the size of a tennis ball. Inside the reactor, these pebbles can be added and removed from the core, along with non-fuel pebbles, to control a steady fission reaction. Refining an originally German design, Eskom and other partners, including the South African Government and British Nuclear Fuels, aim to build a test reactor outside Johannesburg in 2007 and then to market the reactors internationally. Due to business negotiations and technical delays, the reactors are not likely to become commercially available until 2015.

The proposed advantages of these reactors include their small size, increased safety, and the ability to be prefabricated and then shipped to their destination, as opposed to requiring lengthy on-site construction. Pebble bed reactors are cooled by helium gas, which then directly enters a gas turbine to create electricity. This unique feature (lacking the common heat exchanger to make steam to run a turbine) means that the reactors will operate at very high temperatures but will also gain significantly improved fuel efficiency, nearly a 25% increase (Botkin and Se´ller, 2005). The graphite in the fuel pebbles is very stable and is considered a passive control measure that will keep the core from melting, even at very high temperatures, as well as allowing for continuous refueling by removing pebbles from the bottom of the core and adding them to the top. The current design does not include an outer confinement building, the characteristic that allows for the reactor’s significantly smaller size and a testament to the supposed security of the reactor.

The principal critique of the pebble bed design is that it is based on several technological and economic assumptions that have not yet been tested or proven on a commercial scale. For example, the behavior of the fuel pebbles under certain conditions, as well as how the components of the reactor will hold up to such high temperatures, is still unclear (Harding, 2005). In addition, the high cost of the project compares unfavorably to existing technologies such as wind or solar, which do not come with an unresolved waste disposal dilemma or human safety concerns.

Reprocessing

Spent or ‘irradiated’ fuel from any nuclear power plant can be reprocessed to separate the remaining enriched uranium and the newly produced fissile plutonium from the other waste materials for further use. This action requires a separate reprocessing step and is accomplished by means of a chemically intensive method, most often the PUREX method, which stands for ‘plutonium-uranium extraction’. The enriched uranium can then be returned to the regular nuclear fuel cycle and the plutonium can be converted to MOX fuel (short for ‘mixed oxide’), which can be burned in specialized reactors. Reprocessing is a costly undertaking that was aggressively pursued in the early days of nuclear power, when it was feared that uranium stores would be small and prices would thus be high. Because the global price of uranium has remained relatively low, along with technical difficulties in plant construction, continuing waste storage problems, and fears of nuclear proliferation, reprocessing has only been pursued on a large scale by a small number of countries, including France, the UK, Japan, Russia, and India. Other countries either store or transport their spent fuel to these countries for reprocessing, thus creating an international market for reprocessing services. The United States currently has no reprocessing plants in operation, although one was built then shut down and two more were planned and then aborted for technical and regulatory reasons.

It must be noted that separated plutonium can also be used in the production of nuclear weapons, although so-called ‘weapons-grade plutonium’ requires reprocessing and is generated from a shorter irradiation time than that used in power production. Whatever the irradiation time and the resulting combination of plutonium isotopes, the separated plutonium could be used as bomb materials, thus making reprocessing, the resulting plutonium store, and the transportation it requires somewhat of a security concern. For example, stolen plutonium or other radioactive materials could be packaged and detonated with conventional explosives and create a major radiation hazard in an urban area. This so-called ‘dirty bomb’ scenario is currently one of the unresolved security concerns in the United States.

Although reprocessing intuitively seems like an efficient way to recycle waste products into usable fuel, the overall amount of waste produced is greater, although less falls within the high-level classification. The liquid waste from reprocessing is generally vitrified, or immobilized in glass, and then poured into stainless steel containers for storage until a final disposal method is chosen. HLW that is not vitrified is generally put into long-term storage to await final disposal.

Yucca Mountain, Nevada, United States

In 1987, the U.S. government chose Yucca Mountain, Nevada, located around 100 miles from Las Vegas, as its sole prospective site for permanent disposal of HLW from the nuclear power industry. Although approved by the U.S. Congress and the president as a suitable location, the project has faced stiff public resistance, including several lawsuits lodged by the state of Nevada. Scientists have completed an initial two-decade surveying and testing phase, and the project has since applied for licensing to the U.S. Nuclear Regulatory Commission (NRC), which regulates all nuclear power plants in the country. Critics of the project claim that the assumed geologic stability of the Yucca Mountain repository is not well understood and that shipping the country’s nuclear waste to the site itself poses a security threat, making the inherent risks too high to move forward with the project. One proposed alternative is to allow the existing HLW to remain in its storage facilities on-site at the power plants until further research reveals a better option. If the Yucca mountain repository were to be licensed by the NRC, construction would not start until 2010, with waste shipments arriving during the period between 2015 and 2033. The designed capacity of the proposed repository is 70 000 tons of waste (EPA website). A further pressure on the project is the fact that the U.S. government was under a statutory obligation to begin accepting HLW from nuclear reactors in 1998 and it remains in noncompliance with this law, resulting in several pending lawsuits from the nuclear industry.

Economic Competitiveness

An important determinant of future use of nuclear power is how well the industry can compete against other energy competitors in the global marketplace. There are several contradictory views on this subject, ranging from those that endorse a majority nuclear-powered future to those that promote a complete phase out of nuclear energy, all supposedly based on economics.

Some main points of fact are that newly designed nuclear power reactors are marketed as cheaper and faster to build than older models, thus drastically reducing their cost. Yet, many new designs have yet to be proven on a commercial scale and thus there are few data to prove that their projected savings will actually come to fruition. Indeed, many phases of the life cycle of the older generation of nuclear power plants have yet to be witnessed or proven, especially decommissioning costs and nuclear waste storage.

Nuclear electricity is also often billed as a ‘low-carbon’ or ‘carbon-free’ option compared to coal-fired power generation. Although the operating reactor itself does not release carbon dioxide, a life cycle analysis that includes the energy needed to mine, enrich, and transport fuel, as well as to construct the reactor and store waste, reveals the vast amount required of what is currently fossil fuel-based energy (Caldicott, 2005).

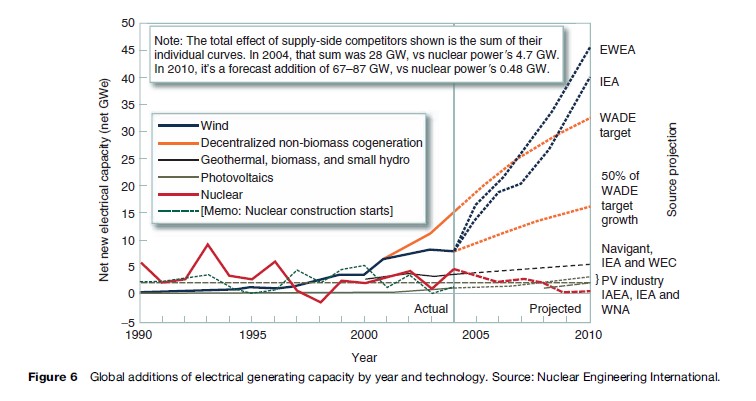

To some, the faster speed of technological advancement, the less intensive technology, and the relative safety of other low-carbon options (such as wind, solar, and geothermal energy) make these choices more economical. Figure 6 illustrates such a projection to the year 2010, and is based on projections made by the representative industry organizations for each energy source.

Conclusion

The human and environmental health effects of nuclear power production vary by each stage in the nuclear fuel cycle. The political, social, and economic factors that inevitably accompany nuclear power decision making add layers of complexity to the issues. Although the nuclear industry continues the quest to improve and market nuclear technologies, the long-term health and environmental effects of the nuclear power cycle, which have long been recognized, still have not been fully resolved. Controversial questions such as where and how to safely store nuclear waste and how to separate, if possible, nuclear power production from nuclear weapons proliferation are two such examples. The level of risk that society deems acceptable may be the most important determinant of the future of nuclear power.

Bibliography:

- Beral V, Roman E, and Bobrow M (eds.) (1993) Childhood Cancer and Nuclear Installations. London: BMJ Publishing Group.

- Botkin DB and Se´ller EA (2005) Environmental Science: Earth as a Living Planet. New York: John Wiley and Sons.

- Caldicott H (2005) Nuclear Reactions: Nuclear Power for Electricity Generation Keeps Generating Heated Debate. IAEA Bulletin 47: 1.